How to Make a Mother Culture for Cheese

Natural cheese-making and making your own lactic acid 'starter culture': is it the panacea of farmhouse cheese-making?

What is natural cheese-making?

Natural cheese-making essentially involves cheese-makers making their own starter cultures rather than buying-in commercial starter cultures to make cheese. But it is difficult to do, and fraught with potential issues.

What is a starter culture?

Making cheese involves acidifying the lactose sugar within milk, turning it into lactic acid. This key step in cheese-making helps set the milk into curd, assists in giving the cheese its flavour, and makes the cheese long-lasting and safe to eat. This process needs bacteria, specifically 'lactic acid bacteria'. Nearly all cheese makers within the UK buy these bacteria in. Much like bakers buy yeast to make bread, cheese-makers buy bacteria to make cheese. They add it to the milk at the beginning of the cheese-making process so it helps kick-start the process.

Making cheese involves acidifying the lactose sugar within milk, turning it into lactic acid. This key step in cheese-making helps set the milk into curd, assists in giving the cheese its flavour, and makes the cheese long-lasting and safe to eat. This process needs bacteria, specifically 'lactic acid bacteria'. Nearly all cheese makers within the UK buy these bacteria in. Much like bakers buy yeast to make bread, cheese-makers buy bacteria to make cheese. They add it to the milk at the beginning of the cheese-making process so it helps kick-start the process.

The lactic acid bacteria are grown by scientists in laboratories, and are sold in sachets, called 'starter culture', and are well-tried and tested. The milk will then acidify as it's supposed to and this will help to produce consistent cheese results. The availability of this 'off-the-shelf starter culture' has helped improved cheese consistency and flavour in many ways.

These sachets are, however, 'some-one else's' bacteria; bacteria not perhaps natural to the cheese-maker's area and milk. On large-scale cheese production, using bought-in cultures is essential because when the milk is coming from multiple farms, often collected over several days, and is pasteurised, the cheese-maker needs to repopulate the milk with lactic acid bacteria in order for it to acidify and to prevent 'bad' pathogenic bacteria from growing. It also helps produce a more consistent product as the cheese-maker will know exactly what the bacteria they add will do.

For more info on starter cultures read: What is starter culture for cheese and what does it do?

What did people do before starter culture could be bought commercially?

Starter culture has only been commercially available since 1893, when the pharmacist Christian Hansen developed it as a commercial product. And it has only very recently been fully adopted by all cheese-makers. Many cheese-making books up until the 1950s talk about cheese-makers making their own starter, or don't mention using a starter at all. Indeed many cheese-makers on the European mainland still make their own starter cultures: all Parmesan, Gruyere, Comte and Etivaz producers on the continent make their own cultures; as do many French goats' cheese-makers.

Prior to the commercial availability of starter culture, all farms and cheese-makers worldwide had to make cheese using their own starter culture – making what is now often called 'natural cheese'.

So why make 'natural cheese'?

If made correctly, a natural cheese will be something completely unique to the cheese-maker and the farm. Rather than treating the milk with pre-made culture, the cheese-maker is allowing their milk to express itself, and the bacteria it naturally contains will grow. The balance and make-up of this indigenous microbial community will be exclusive to each location and each cheese, which will give a cheese with a truly unique flavour. This is cheese in its purest form – a true reflection of where it is made: the 'terroir'.

If made correctly, a natural cheese will be something completely unique to the cheese-maker and the farm. Rather than treating the milk with pre-made culture, the cheese-maker is allowing their milk to express itself, and the bacteria it naturally contains will grow. The balance and make-up of this indigenous microbial community will be exclusive to each location and each cheese, which will give a cheese with a truly unique flavour. This is cheese in its purest form – a true reflection of where it is made: the 'terroir'.

At present in the British Isles there are only six cheese-makers using this 'natural way': Martin Gott (of Holker Farm – maker of St James), Frank Shinnuck (of Fermoy Cheese), Innes Cheese, KappaCasein (maker of Bermondsey Hard Pressed), Sleight Farm (maker of Tymsboro) and Dudley Martin (at Ludlow Food Centre).

But natural cheese-making does have its disadvantages.

What are the disadvantages of making a natural starter culture?

A lab-made starter culture bought from dairy scientists like Hansen's is tried and tested, and will acidify the milk as required; the cheese-maker will know exactly what it is going to do. In this way it is safer to use (as bad bacteria are outcompeted) and will produce more consistent results. This is essential for any producer selling to a larger market, or where a customer doesn't get to sample the cheese each time just before they buy – the producer doesn't want the cheese to be different each time!

But when using homemade starter cultures, the culture is constantly evolving so will produce different results each day. A good cheese-maker can mitigate the risks, but there is no doubt the cheese may not be consistent or standard every time. Which can be exciting, yes, but also challenging – the cheese will be more variable and sometimes, if the process is not done correctly, can be tainted by off-flavours. As the cultures are also wild and un-refined, the cheese-maker will never know for sure what acidity they will create or what speed they will run at, so knowing how much to use, when to change them and how to maintain them is an art or skill learned through experience.

A cheese-maker making their own starter culture needs to know what they are doing to avoid cultivating 'bad' pathogenic bacteria. It is not for everyone. The cheese-maker must have really close control over their milk quality and follow correct methods to make their own starter safely. All of the UK natural cheese-makers mentioned above have to thoroughly test their cheese and starter culture for bad bacteria, and have spent a lot of time working on methods to safely produce their own starter.

Indeed of the producers who make natural cheese in the UK have made cheese for many years using more commercially-available starters before they felt confident enough to start to develop their own.

There is also an argument that the selective cow breeding and modern-day milking and cleaning methods used in the quest for 'clean' milk has removed a lot of the natural population of lactic acid bacteria within the environment and milk, so making your own starter culture might actually prove impossible to do in any case!

How does a cheese-maker make their own starter culture for cheese?

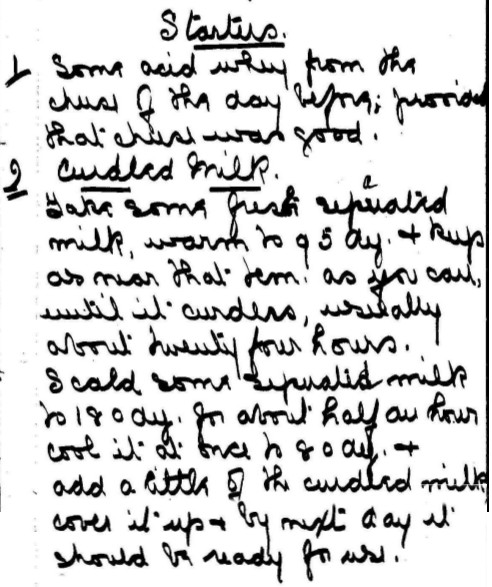

Andy Swinscoe's great grandma's notebook (from being a dairy maid in 1912) lists a couple of ways to make starters, which other old texts and current industry practice seems to confirm as the most commonly accepted methods:

Andy Swinscoe's great grandma's notebook (from being a dairy maid in 1912) lists a couple of ways to make starters, which other old texts and current industry practice seems to confirm as the most commonly accepted methods:

- Hand milking one fit animal into a clean pail (after discarding the first bit of milk from the udder, and using minimal machinery to eliminate the chances of cross contamination).

To reduce risk many producers will carry out this step multiple times with different animals so if one incubated batch fails, they have a replacement.

This hand-milked fresh raw milk is then incubated overnight at around 20C. It should then sour and can be treated as the 'starter culture' and added to the fresh milk in the morning to start the process of making cheese.

Before using the incubated milk, it should be tested to see if it has a good set, clean sharp flavour and measured acidity – looking out for potential problems such as floating or slimy curd, gassy curd and/or off smells/tastes.

The incubated starter could then be halved, half used for making cheese, and the other half used to make the next day's starter by adding it to fresh sterile milk and incubating again – a bit like for making sourdough bread.

For some types of cheese production, mainly continental Alpine styles which involve heating the curd, the method of making the cheese means that using their own starter culture is an easier/safer thing to do: they heat up the starter culture or leftover whey and incubate it at higher temperatures (often 38-50C+). - Another method is to use whey from the previous day's cheese-make and 'carry the culture forward' into the fresh milk. This relies on the producer making cheese every day and having some whey to start with, or a friendly neighbour farm they can borrow it from!

To eliminate the risk of passing bad bacteria 'down the chain across successive batches of cheese', the whey should reach a low pH (<4.6) and be tested (in a clean pot of milk, and by a laboratory). - There are some advocates of using kefir made from kefir grains to make cheese, although the use of kefir is debated within the farmhouse and natural cheese community as kefir itself does contain lactic acid bacteria, but it does contain other fermenting bacteria and yeasts which could potentially influence the cheese-make in an unfavourable way.

Kefir grains are a naturally occurring symbiotic 'live' grain containing many different yeasts and bacteria which live together in a 'grain' which looks like a tiny cauliflower, and can be used to acidify and ferment milk and other liquids.

Some old methods don't mention adding any of this pre-cultured milk or homemade starter at all and the milk would still acidify. There are still some producers on the continent who use these methods. They tend to be milking traditional cow breeds such as Salers, and wooden equipment which has been used for many years and is soaked and cleaned in whey (not using any aggressive chemicals at all). These utensils effectively hold the bacteria within the wood. Salers du Buron, Ragusano and Bleu de Termignon are all still made like this.

Some producers tend to just let the evening milk sour overnight by leaving it out warm in shallow pans, before adding it to the morning milk. Although it works for some makers, most farm-producers today have a more hygienic and 'cleaner milk' environment than the past, so the chance of their milk generating acidity by these methods in sufficient time to make good cheese is rare.

So does natural cheese have a future?

Let's hope so! But even in Italy and France the practices of making their own starter are dying out, because buying-in pre-made starter culture does make the whole process of making cheese easier.

Many French and Italian affineurs, as well as The Slow Food Movement in Italy, are therefore trying to document and encourage those still making 'natural cheese'; as are those at the forefront of farmhouse cheese in the UK.

Natural cheese is definitely harder to make. It does have consistency issues. It should be only carried out by those who are really confident of, and have control over their raw milk. But tied into many other factors (milk quality, animal breed and feed), it can help the cheese to become a complete expression of where it is made – totally unique to the producer. Isn't that what farmhouse cheese-making is all about?

Click here to view the natural cheeses currently in stock >

(Recently Martin Gott in England got a Nuffield Scholarship to research further "The prevalence and importance of indigenous bacterial cultures in raw milk cheese"; in order to increase our understanding of natural cheese and bacteria [listen to a podcast with Martin talking about natural cheese here>].)

Related Articles

How to Make a Mother Culture for Cheese

Source: https://www.thecourtyarddairy.co.uk/blog/making-ageing-cheese/natural-cheese-making-and-making-your-own-lactic-acid-starter-culture-is-it-the-panacea-of-farmhouse-cheese-making/

0 Response to "How to Make a Mother Culture for Cheese"

Post a Comment